Modula Flexibox

The future of fast and flexible order fulfilment

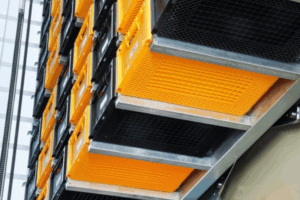

The Modula Flexibox is a cutting-edge automated storage solution designed to streamline warehouse operations.

With its modular design, Flexibox adapts to your storage needs, increasing storage density and optimising picking times.

Perfect for retail, e-commerce, automotive and distribution, it handles large order volumes while ensuring ergonomic operation and maximising space.

Key Benefits

- Local engineers and spare-parts stock minimise downtime.

- Certified Modula specialists available on-site or remotely.

- Modular architecture grows with your business.

Modula Flexibox Benefits

|

|

||||

|

|

||||

|

|

How Does It Work?

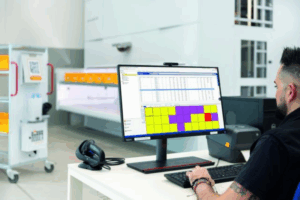

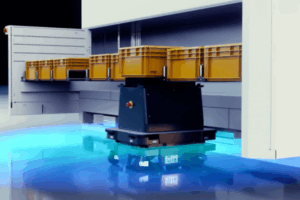

It is engineered for peak efficiency with a central elevator featuring a telescopic fork that retrieves up to 9 bins at once. Integrated WMS software intelligently groups multiple order references within a single tray, reducing operator wait times and speeding up order fulfilment.

When an order is placed, Flexibox analyses all order lines and uses the elevator to collect the necessary bins. These bins are delivered on a service tray directly to the picking bay, allowing operators to pick multiple order lines in one go.

While processing one tray, the system simultaneously prepares the next, maintaining a continuous workflow and delivering a consistently high picking rate.

DMD Storage Group has been in business for 30 years; a local Perth business, we have expanded our warehouse storage solutions over the years and always strive to ensure we source the right suppliers for our client’s needs. We are excited to work with and supply Modula Machines to our client base. Full, hands-on support is available right here in Australia.

Modula Models also include:

Modula Lift

- Maximise Space

- Optimal Load Capacity

- Internal & External Bays

- Single & Dual Delivery

Modula Next

- Great Security Control

- High Picking Efficiency

- Complete Flexibility

Modula Slim

- Storage Density

- High Picking Efficiency

- Low Energy Consumption

- Complete Flexibility

Technical Specifications

-

- Unit Height: 3,300 mm – 20,000 mm

- Bin Size: 400 x 600 mm

- Bin Payload: Max 35 kg

- Models Available: ME (3 bins), MA (4 bins), MC (5 bins), MX (6 bins), ML (9 bins)

- Types of Bay: Internal, External, Single & Dual Delivery

Advanced Features

- Scalable Design: Increase capacity by adding trays or units as your business grows.

- Fast Item Retrieval: Single-item access without moving other bins.

- Smart Orders Preparation: Automated pre-arranging of trays during idle time for zero downtime.